OIL HOUSE COMPANY Tubular Running Services is committed to the delivery of quality equipment and personnel. We offer our customers a comprehensive casing and handling packages

Hydraulic Power Tong

OIL HOUSE COMPANY casing power tongs are Selected to suit high torque casing, providing maximum torque with reliable performance. We provide a full range of casing sizes to meet the varying needs of each client. We offer non-marking jaws and dies to handle and save the premium tubing string and corrosion resistant alloys (CRA).

Power Back Unit

Built and certified to the highest industry safety standards with a proven history of success in the field, Our power back units are designed to provide a reliable power source for a wide range of hydraulic requirements for onshore and offshore applications.

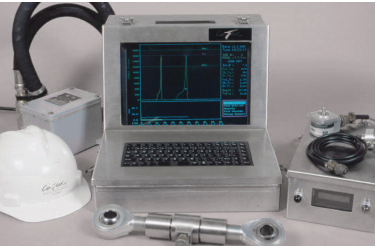

JAM System

Our Joint Analyzed Make-Up unit is designed to enable users to fully monitor connections in breaking out and making up during the operation, securing against any collapse, thread damage or uncontrolled torque.

Fill up Tools

To conserve rig time for our clients during casing running operations, OIL HOUSE COMPANY offers its Casing Circulating Fill-up and Flow Back Tool, compatible with both the Top Drive and Kelly systems

Handling Tools

Our casings handling tools are sourced to support casing and tubing operations to provide a safer casing running environment by eliminating high-risk operations. We offer quality Rotary Hand Slips and Bowl Slips, side door elevators, spider slips, elevators, Flush Mounted Spiders (FMS) and power slips in a variety of latch types, insert types and slip assemblies to meet client requirements.

Moreover, we are proposing New Technology to the market.

Casing Running Tools

Casing running tools provide a mechanized, safe and cost-effective way to run and make-up casing.

Casing running tools provide the ability to rotate, circulate and reciprocate pipe simultaneously during cementing operations.

Works with the top drive to easily attain smooth make up with no bending load and with precise control on final torque. It also decreases the amount of equipment required onsite and provides safety benefits in several ways. Casing running tool replaces typical conventional equipment such as the power casing tong, casing elevators and spiders and a dedicated hydraulic power unit. This decreases manpower required, saves on equipment costs and provides a less cluttered, and thereby a safer, working environment. It also eliminates the need to have a stabbing board operator working, which has been identified as a top factor that can cause lost-time incidents during operations.